What is Seam Welding?

Seam welding is a sophisticated welding process where overlapping spot welds are used to create a continuous, durable joint. This method ensures a seamless connection, making it ideal for applications requiring airtight or liquid-tight seals. Seam welding is used in various industries, including automotive, aerospace, and construction.

Types of Seam Welding

There are four main types of seam welding – resistance seam welding, arc seam welding,laser seam welding and ultrasonic seam welding.

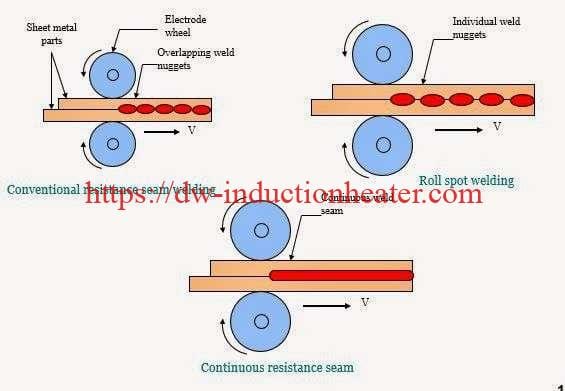

Resistance Seam Welding

Resistance seam welding uses electrical resistance to create heat between overlapping metal sheets. The heat generated softens the metals, allowing them to fuse together. This method is commonly used for joining sheet metal parts in automotive manufacturing.

The process involves placing two or more sheets of metal on top of each other with a small gap between them. Metal electrodes then apply pressure on the overlapping area while an electric current passes through the material. As a result, a series of overlapping spot welds are created, forming a continuous seam. The heat generated during this process also causes the metals to reach their melting point, creating a strong bond.

Parameter | Description | Value |

|---|---|---|

Welding Current | The electric current used during welding | 5,000 – 15,000 Amps |

Electrode Force | The pressure applied by the electrodes | 200 – 1,000 Newtons |

Weld Time | The duration of current flow | 0.1 – 3 seconds |

Sheet Thickness | Thickness of sheets suitable for welding | 0.5 – 3 mm |

Electrode Material | Material of the welding electrodes | Copper or Copper alloys |

|

Arc Seam Welding

Arc seam welding, also known as gas tungsten arc welding (GTAW), uses an electric arc to create the heat needed for fusion. This method is commonly used for joining thicker materials or non-ferrous metals such as aluminum and copper.

The process involves using a non-consumable tungsten electrode to create an arc between the two metal pieces. The heat generated by the arc melts the edges of the overlapping metal sheets, creating a molten pool that fuses them together. As with resistance seam welding, a series of overlapping spot welds are created to form a continuous joint.

Both resistance and arc seam welding provide strong and durable joints, but each method has its own advantages and is better suited for different applications.

Laser Seam Welding

Laser seam welding is a precision welding technique that uses a focused laser beam to generate the heat required for fusing materials. This method is ideal for applications requiring high accuracy and minimal thermal distortion, such as in the aerospace, automotive, and electronics industries.

The laser beam produces a concentrated heat source, allowing for deep penetration and narrow weld seams, even on complex geometries. Laser seam welding is particularly effective for thin materials or dissimilar metal joints. However, it requires advanced equipment and precise control, often making it a costlier option compared to traditional welding methods.

Ultrasonic Seam Welding

Ultrasonic seam welding relies on ultrasonic vibrations to create heat through friction between the materials being joined. This technique is commonly used for non-metallic materials, such as plastics and certain composites, and has growing applications in textile and packaging industries.

The process involves applying controlled ultrasonic vibrations while pressing the materials together. The energy from these vibrations softens or melts the materials at the weld interface, creating a seamless bond upon cooling. Ultrasonic seam welding is valued for its speed, cleanliness, and the fact that it does not require additional filler materials or adhesives.

Advantages of Seam Welding

- Durable joints: Seam welding creates a continuous joint, making it stronger and more resistant to pressure or stress.

- Airtight or liquid-tight seals: The nature of seam welding makes it ideal for creating airtight or liquid-tight seals, preventing leaks in various applications.

- High production rates: Both resistance and arc seam welding are automated processes that can produce a large number of welds quickly, making them highly efficient for mass production.

- Versatility: Seam welding can be used to join a variety of materials, including different types of metals and non-metallic materials.

- Reduced distortion: Laser seam welding and ultrasonic seam welding are known for their ability to minimize thermal distortion, making them suitable for precision applications.

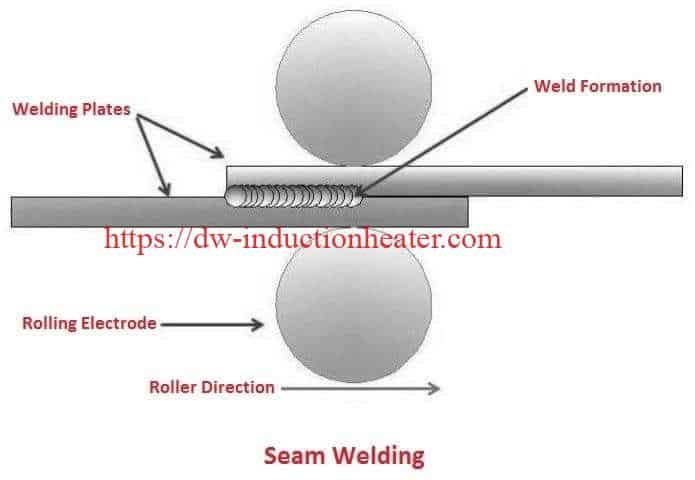

How It Works

- Pressure and Current: Seam welding relies on rotating wheels or rollers that apply consistent pressure and electrical current along the seam of the materials being joined.

- Continuous Weld: These rollers create overlapping spot welds, forming a continuous and strong joint.

- Material Compatibility: This process can be applied to a variety of metals, including steel, aluminum, and other conductive materials. It can also be used to join non-metallic materials, such as plastics and composites.

- Automation: Seam welding can easily be automated for high-volume production, with the use of robotic equipment and advanced control systems.

Seam welding is a versatile method of joining materials, offering numerous advantages including durability, versatility, and high production rates. Whether it is for automotive manufacturing or creating airtight seals in packaging, seam welding plays an essential role in various industries. With advancements in technology and equipment, this process continues to evolve and expand its applications in modern manufacturing. So next time you come across a seamless joint or robust seal, remember that it was likely created through the process

Key Applications

Seam welding is highly valued in industries requiring precision and reliability. Common applications include:

- Fuel Tanks: Creating liquid-tight seals for automotive and industrial uses.

- Mufflers: Ensuring strong and durable connections in exhaust systems.

- Containers: Manufacturing airtight containers for food, chemicals, and other sensitive materials.

- Heat Exchangers: Seam welding is used to fabricate leak-proof joints in heat exchanger tubes and plates, ensuring efficient thermal transfer.

- Transformers: It plays a crucial role in assembling cores and casings for electrical transformers, providing structural integrity and electrical performance.

- Batteries: The process is vital in sealing battery casings, ensuring durability and protecting internal components from external elements.

- Aerospace Components: Seam welding contributes to the assembly of high-precision components in the aerospace industry, where strength and reliability are critical.

Why Choose Seam Welding?

The ability to produce strong, continuous joints with consistent quality makes seam welding a go-to method in manufacturing processes. It’s especially useful for mass production where airtight or liquid-tight integrity is essential.

Seam welding plays a critical role in modern manufacturing, providing reliable and efficient solutions for projects that demand precision, strength, and durability. As advances in technology continue to improve seam welding processes, its applications and effectiveness will only grow. So if you want to achieve high-quality, consistent welds for your project, consider seam welding as a top choice.

With its versatility and ability to produce airtight and liquid-tight seals, there’s no doubt that seam welding will remain an important part of the manufacturing industry for years to come. As industries evolve and new materials are developed, advancements in seam welding techniques will continue to shape the way we join metals and other materials with unparalleled precision and efficiency. Keep exploring different welding methods like spot welding or TIG welding that might be better suited for specific applications or materials.

Conclusion

Seam welding is a specialized welding process that offers unique advantages for joining materials in various industries. With different types of seam welding available, each with its own benefits, this technique continues to evolve and find new applications in manufacturing processes. From creating durable connections to ensuring airtight seals, seam welding plays an essential role in building strong and reliable products. So, it has been widely adopted by industries all around the world. As technology advances, we can expect to see further advancements in seam welding techniques, making it an even more integral part of modern manufacturing. So, seam welding is a crucial and constantly evolving process that plays a vital role in creating durable and reliable products used in our daily lives.

So, it’s important to understand the different types and advantages of seam welding to make informed decisions when choosing the best method for a specific application. Whether it’s for automotive or aerospace components, electronic devices, or packaging materials, seam welding offers the precision and strength needed to create high-quality products. With ongoing research and development, we can look forward to even more efficient and versatile seam welding techniques in the future.