-

1/5

-

2/5

-

3/5

-

4/5

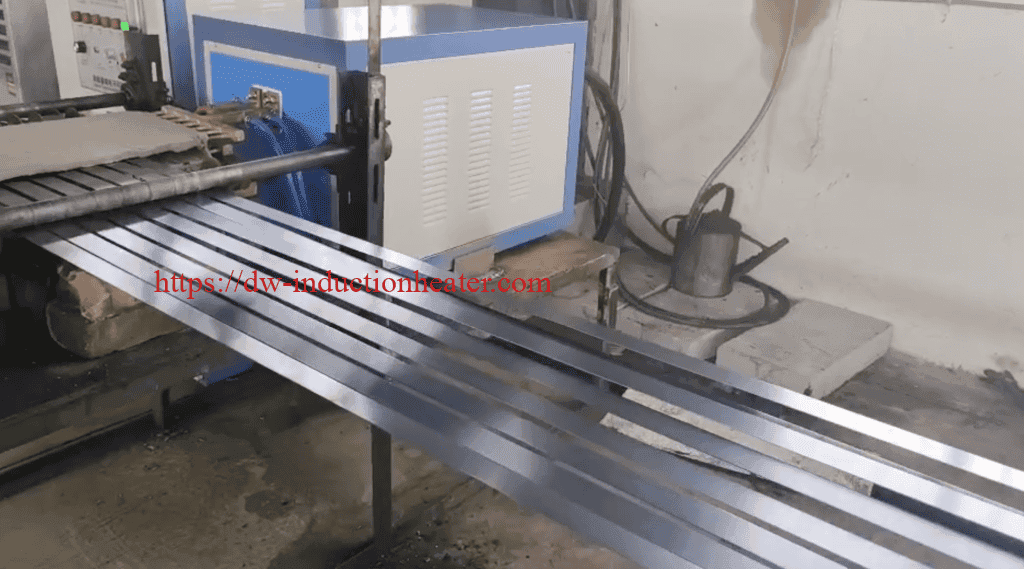

Continuous Induction Steel Strip Annealing Machines

Description

Continuous Induction Steel Strip Annealing Machine: Boosting Efficiency and Product Quality

In today’s highly competitive steel industry, manufacturers are constantly seeking new ways to increase throughput, lower costs, and maintain stringent quality standards. Continuous induction steel strip annealing machines have emerged as a game-changing technology, enabling faster processing times, higher energy efficiency, and enhanced metallurgical properties—particularly when compared to traditional furnace-based systems.

What is a Continuous Induction Steel Strip Annealing Machine?

Unlike conventional furnace-based systems, induction annealing machines use electromagnetic induction to heat steel strips rapidly and evenly. The strip is passed continuously through induction coils, where it is exposed to an alternating magnetic field that generates heat directly within the material. This process enables instant, controllable heating and cooling cycles, optimizing both metallurgical properties and operational efficiency.

Annealing is a heat-treatment process that alters a material’s microstructure, making it more ductile, softer, and relieving internal stresses. Unlike conventional furnace-based annealing, induction annealing uses electromagnetic fields to generate eddy currents directly within the steel strip. The resulting heat is localized, rapidly raising the strip’s temperature with minimal energy losses.

In a continuous induction steel strip annealing machine, the strip travels through multiple induction coils and controlled cooling sections without stopping. This continuous flow translates into higher throughput, reduced downtime, and lower operational costs.

Key Advantages of Continuous Induction Annealing

- High Throughput

- The continuous line operation eliminates batch cycling, reducing wait times and maximizing output.

- Energy Efficiency

- Concentrated heating in the strip itself significantly minimizes heat wastage to surrounding equipment and atmosphere.

- Uniform Temperature Control

- Real-time feedback systems help maintain tight temperature tolerances across the strip width and length, ensuring consistent metallurgical quality.

- Space-Saving Design

- Induction systems typically occupy a smaller footprint than large furnaces, making them suitable for facilities with limited floor space.

- Reduced Oxidation and Scaling

Process Overview

- Uncoiling and Infeed

- Steel strip is uncoiled, cleaned, and fed into the continuous line under controlled tension.

- Any surface contaminants or scales are minimized to improve heating uniformity.

- Induction Heating Zone

- High-frequency electromagnetic fields induce eddy currents in the strip, elevating its temperature rapidly.

- Multiple coils (or zones) can be configured for progressive temperature rises or specific thermal profiles.

- Soak/Hold Section

- If required, the strip is held at the target annealing temperature for a specific dwell time to ensure uniform grain structure and stress relief.

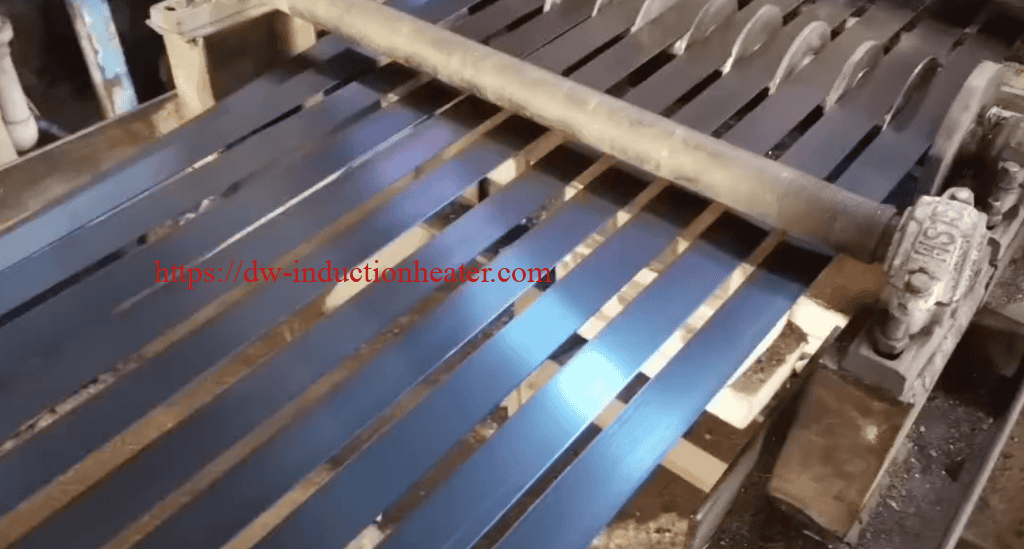

- Cooling

- The strip transitions into a cooling section, which may use air, water, or inert gas jets to achieve the desired cooling rate.

- Controlled cooling rates help define final mechanical properties, such as hardness and ductility.

- Recoiling or Further Processing

Technical Parameters Tables

Below are two tables summarizing typical machine performance and material handling specifications for a continuous induction steel strip annealing machine. Actual values may vary depending on specific requirements, manufacturers, and steel grades.

Table 1: Machine Performance Parameters

| Parameter | Typical Range / Value | Remarks |

|---|---|---|

| Power Output (kW) | 150 – 1000 kW+ | Higher power allows faster heating and thicker strip processing. |

| Frequency Range (kHz) | 10 – 250 kHz | Affects heating penetration depth; higher frequencies favor thinner strips. |

| Efficiency (%) | 70 – 90% | Efficiency gained from localized heating (strip only). |

| Line Speed (m/min) | 10 – 200+ | Adjusted based on thickness, desired output, and soaking requirements. |

| Temperature Range (°C) | 400 – 1100+ | Carbon steels often 600 – 900 °C; specialized alloys may go higher. |

| Temperature Tolerance | ±2 – ±5 °C | Ensures uniform metallurgical properties across the strip. |

| Number of Heating Zones | 2 – 6+ | Multiple zones allow segmented or staged heating profiles. |

| Control System | PLC/SCADA with HMI | Real-time monitoring, data logging, and closed-loop temperature control. |

| Cooling Method | Air Cooling, Water Spray, Inert Gas | Selected based on steel grade and metallurgical requirements. |

| Machine Footprint | Space-Efficient, Modular | Typically smaller than a furnace; can be customized to facility layout. |

Table 2: Material Handling Parameters

| Parameter | Typical Range / Value | Remarks |

|---|---|---|

| Steel Strip Thickness | 0.2 – 6.0 mm | Thicker materials may require more power for through-heating. |

| Strip Width | 50 – 1500 mm | Wider strips may use multiple coils side by side or specially designed coil geometries. |

| Coil Weight | Up to 25 Tons (typical) | Machine infeed and outfeed systems must handle large coils safely. |

| Surface Condition | Pickled, Scaled, Oiled | Proper cleaning pre-process is crucial for uniform heating. |

| Soak/Hold Time | 2 – 30+ seconds (typical) | Ensures consistent microstructure and mechanical properties. |

| Tension Control | 50 – 250 N/mm² (approx.) | Maintains strip stability in high-speed operations. |

| Exit Temperature | 40 – 200 °C (depending on process) | The final temperature for safe recoiling or next stage operations. |

| Recoiling Speed | Matches Annealing / Cooling Speeds | Continuous operation avoids production bottlenecks. |

Table 3: Atmosphere Control Parameters

Table 3: Atmosphere Control Parameters

| Parameter | Standard Annealing | Specialized Annealing |

|---|---|---|

| Atmosphere Type | N₂/H₂ mixture | N₂/H₂, 100% H₂, or vacuum |

| Hydrogen Content | 5-15% | Up to 100% |

| Oxygen Content | <20 ppm | <5 ppm |

| Dew Point | -40 to -20°C | -60 to -40°C |

| Pressure Control | ±0.5 mbar | ±0.2 mbar |

| Gas Purification | Standard | Advanced multi-stage |

Data Analysis: Performance Insights

Many steel processors have documented substantial improvements after installing continuous induction steel strip annealing machines. Below are some key data points from real-world implementations:

- Energy Savings

- Operators often observe a 10–20% drop in energy consumption compared to gas-fired furnaces, thanks to localized heating.

- Shorter heat-up times further reduce the total operating hours at peak energy load.

- Throughput Increments

- By maintaining full-line continuity, production throughput can increase by 15–30%.

- Automated loading, uncoiling, and recoiling systems reduce downtime between coils.

- Quality Enhancements

- Precise temperature control leads to tighter tolerances in tensile strength, yield strength, and toughness—meeting stricter industry specifications.

- Lower oxidation and scale formation lead to a smoother surface finish, especially crucial for high-end automotive or appliance applications.

Quality Control Metrics Before and After Implementation of Advanced Analytics

| Quality Metric | Before Implementation | After Implementation |

|---|---|---|

| Mechanical Property Deviation | ±7-10% | ±2-3% |

| Surface Defect Rate | 2.5% | 0.8% |

| Dimensional Tolerance Consistency | 92% | 99.1% |

| Customer Rejection Rate | 1.2% | 0.15% |

| Premium Grade Qualification Rate | 78% | 96% |

- Scrap Reduction

- Fewer temperature fluctuations and more uniform mechanical properties minimize rejections during manufacturing, lowering scrap rates by up to 10–15%.

Environmental Impact Comparison (per ton of processed steel)

| Impact Factor | Conventional Annealing | Induction Annealing | Reduction |

|---|---|---|---|

| CO₂ Emissions | 95-120 kg | 35-60 kg | 50-70% |

| Water Consumption | 3.5-5.0 m³ | 0.8-1.5 m³ | 70-80% |

| NOₓ Emissions | 0.15-0.25 kg | 0.02-0.05 kg | 80-90% |

| Waste Heat | 35-45% of input energy | 10-15% of input energy | 65-75% |

Real-World Use Cases

1. Automotive Steel Processing

A major automotive steel plant upgraded its annealing line from conventional furnaces to a state-of-the-art continuous induction system:

- Results:

- Energy usage dropped by 30% annually.

- Throughput increased from 80 to 180 m/min.

- Reduction in rework and defects: Finished strips consistently met strict flatness and strength tolerances required for automotive body panels.

- Operational footprint reduced: The induction line occupied less floor space, increasing plant flexibility.

2. Electrical Steel for Transformers

A precision manufacturer of electrical steel for transformer laminations implemented an induction annealing system:

- Benefits Achieved:

- Consistent grain structure, improving magnetic properties of the steel.

- Contamination-free: Protective H₂/N₂ atmospheres prevented oxidation, yielding brighter, cleaner strips.

- Faster changeovers: Digital recipe management streamlined product switches, decreasing downtime.

Conclusion

A continuous induction steel strip annealing machine represents a major leap forward in steel processing technology—offering better energy efficiency, higher throughput, and superior product quality. With precise temperature control, minimal oxidation, and flexible line configurations, it is poised to serve diverse applications in industries ranging from automotive and construction to home appliances and electrical steel production.

By studying the technical parameters and closely analyzing performance metrics, steel producers can seamlessly integrate continuous induction annealing into existing lines or build new facilities tailored for maximum efficiency. The result? A leaner, greener, and more competitive operation ready to meet the evolving demands of the global steel market.

Frequently Asked Questions (FAQ)

Q: What materials are suitable for induction annealing?

A: Carbon steel, alloy steel, and stainless steel strips are commonly processed with induction annealing machines.

Q: How does induction annealing improve energy efficiency?

A: Induction heating delivers energy directly to the strip material, reducing radiant and convective losses typical of furnace-based systems.

Q: Can induction annealing lines be integrated with existing automation?

A: Yes, most systems offer PLC and HMI/SCADA integration for seamless control and monitoring.

Table 3: Atmosphere Control Parameters

Table 3: Atmosphere Control Parameters